Flexible hoses play a crucial role in countless industrial, commercial, and residential applications. These versatile conduits allow for the efficient transfer of liquids, gases, and even solid materials through systems that require movement, vibration absorption, or complex routing. Understanding the various types of flexible hoses, their specific applications, and inherent benefits can help you select the right product for your needs. This comprehensive guide explores everything you need to know about flexible hoses and their importance in modern systems.

What Is Flexible Hoses?

Flexible hoses are pliable tubes designed to transport fluids, gases, or granular solids from one location to another. Unlike rigid piping, flexible hoses can bend, twist, and adapt to various configurations without compromising their structural integrity. The design of flexible hoses incorporates materials that provide both strength and elasticity, allowing them to function effectively under diverse conditions.

Types of Flexible Hoses

The market offers numerous types of flexible hoses, each engineered for specific applications:

- Rubber Flexible Hoses

Rubber flexible hoses represent one of the most common types available. They offer excellent flexibility, durability, and resistance to abrasion. These hoses can withstand extreme temperatures and are ideal for transferring various substances including water, oil, and chemicals.

- Metal Flexible Hoses

Metal flexible hoses, typically made from stainless steel or bronze, provide superior strength and pressure resistance. These hoses can operate in high-temperature environments while maintaining their structural integrity. Industries often employ metal flexible hoses for steam transfer, hot oil systems, and high-pressure applications.

- Plastic Flexible Hoses

Lightweight and economical, plastic flexible hoses suit moderate-pressure applications. These hoses resist corrosion and work well with water, air, and certain chemicals. PVC, polyethylene, and nylon represent common materials used in plastic flexible hoses.

- Composite Flexible Hoses

Combining the benefits of different materials, composite flexible hoses deliver enhanced performance characteristics. These hoses might incorporate layers of rubber, fabric, and metal to achieve specific properties such as chemical resistance, pressure handling, and flexibility.

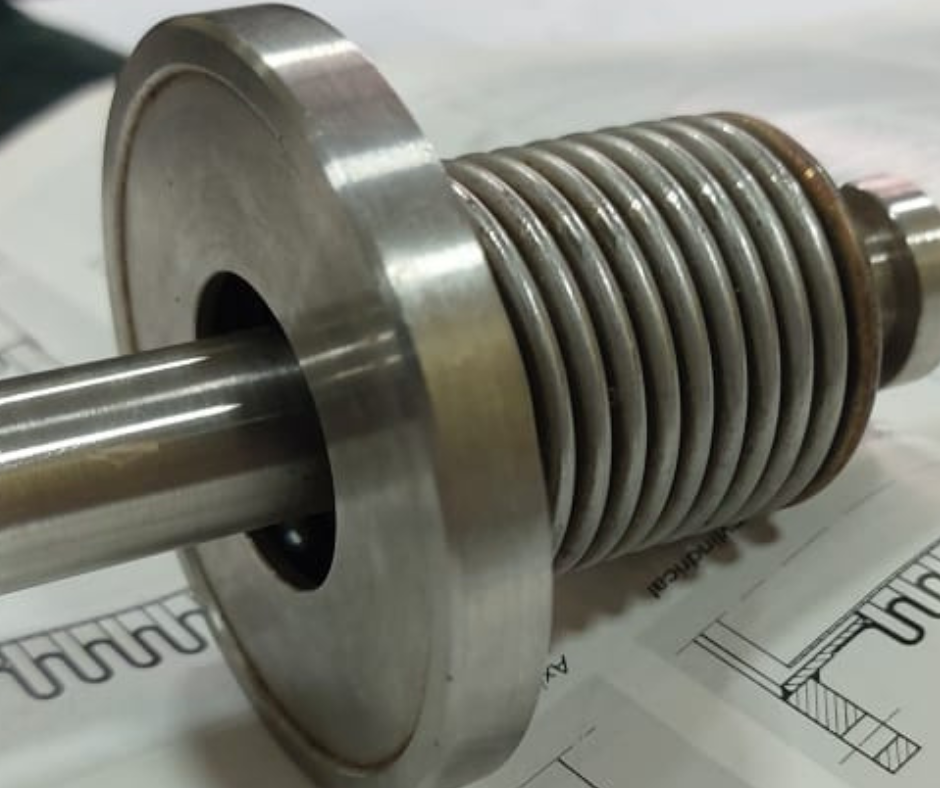

- Bellows-Type Flexible Hoses

Bellows-type flexible hoses feature accordion-like convolutions that provide exceptional flexibility and movement in multiple directions. These specialized hoses excel in applications requiring compensation for thermal expansion, misalignment, and vibration absorption. Made from materials like stainless steel, rubber, or specialized polymers, bellows hoses maintain their integrity while accommodating significant movement, making them ideal for precise industrial applications.

Common Applications of Flexible Hoses

Flexible hoses serve numerous industries and applications:

- Industrial Applications

In manufacturing and processing facilities, flexible hoses connect machinery components, transfer materials between equipment, and provide utility services. The ability of flexible hoses to absorb vibration makes them ideal for connections to moving equipment. Bellows configurations are particularly valuable in high-temperature industrial environments where thermal expansion must be accommodated.

- Plumbing and HVAC

Flexible hoses simplify installation in plumbing and HVAC systems. Their adaptability allows for connections in tight spaces where rigid pipes would prove problematic. From toilet supply lines to air conditioning units, flexible hoses offer convenient solutions. Bellows-style connectors provide additional movement capability in systems subject to temperature fluctuations.

- Automotive Systems

Modern vehicles utilize flexible hoses throughout their design. Fuel lines, brake systems, and cooling circuits all rely on specialized flexible hoses that can withstand automotive fluids and operating conditions. Exhaust systems often incorporate bellows sections to absorb engine movement and vibration.

- Agricultural Operations

Farming equipment depends on flexible hoses for hydraulic systems, irrigation setups, and material transfer operations. The durability of these hoses allows them to perform reliably in challenging outdoor environments.

Benefits of Flexible Hoses

The popularity of flexible hoses stems from their numerous advantages:

- Easy Installation

Unlike rigid piping, flexible hoses require no complex measuring, cutting, or fitting. This simplicity reduces installation time and labor costs significantly. Flexible hoses can navigate around obstacles and accommodate misalignments between connection points. Bellows designs offer additional installation benefits when dealing with systems that experience movement or thermal cycling.

- Vibration Absorption

Flexible hoses excel at dampening vibrations and movement between connected components. This capability prevents damage to equipment and reduces noise in operational systems. In applications with moving parts, flexible hoses provide the necessary give without compromising flow capacity. The corrugated structure of bellows provides superior vibration dampening compared to other flexible hose types.

- Space Efficiency

The adaptable nature of flexible hoses allows for efficient use of limited space. These hoses can bend around corners and follow complex paths that would be impossible with rigid piping solutions. This flexibility proves particularly valuable in crowded mechanical rooms or confined installations.

- Reduced Stress on Connections

Systems using flexible hoses experience less stress at connection points. This reduction in mechanical stress extends the lifespan of equipment and minimizes maintenance requirements. Flexible hoses effectively absorb thermal expansion and contraction that might otherwise damage connections. Bellows sections are specifically designed to handle axial, lateral, and angular movements while maintaining seal integrity.

Selecting the Right Flexible Hoses

When choosing flexible hoses for your application, consider these factors:

-

- Media being transported (compatibility with material)

-

- Operating pressure and temperature ranges

-

- Required flexibility and bend radius

-

- Environmental conditions and exposure

-

- Regulatory compliance and certification needs

-

- Need for bellows-type construction for extreme movement or thermal expansion requirements